Week 4:Electronics Production

Outcomes

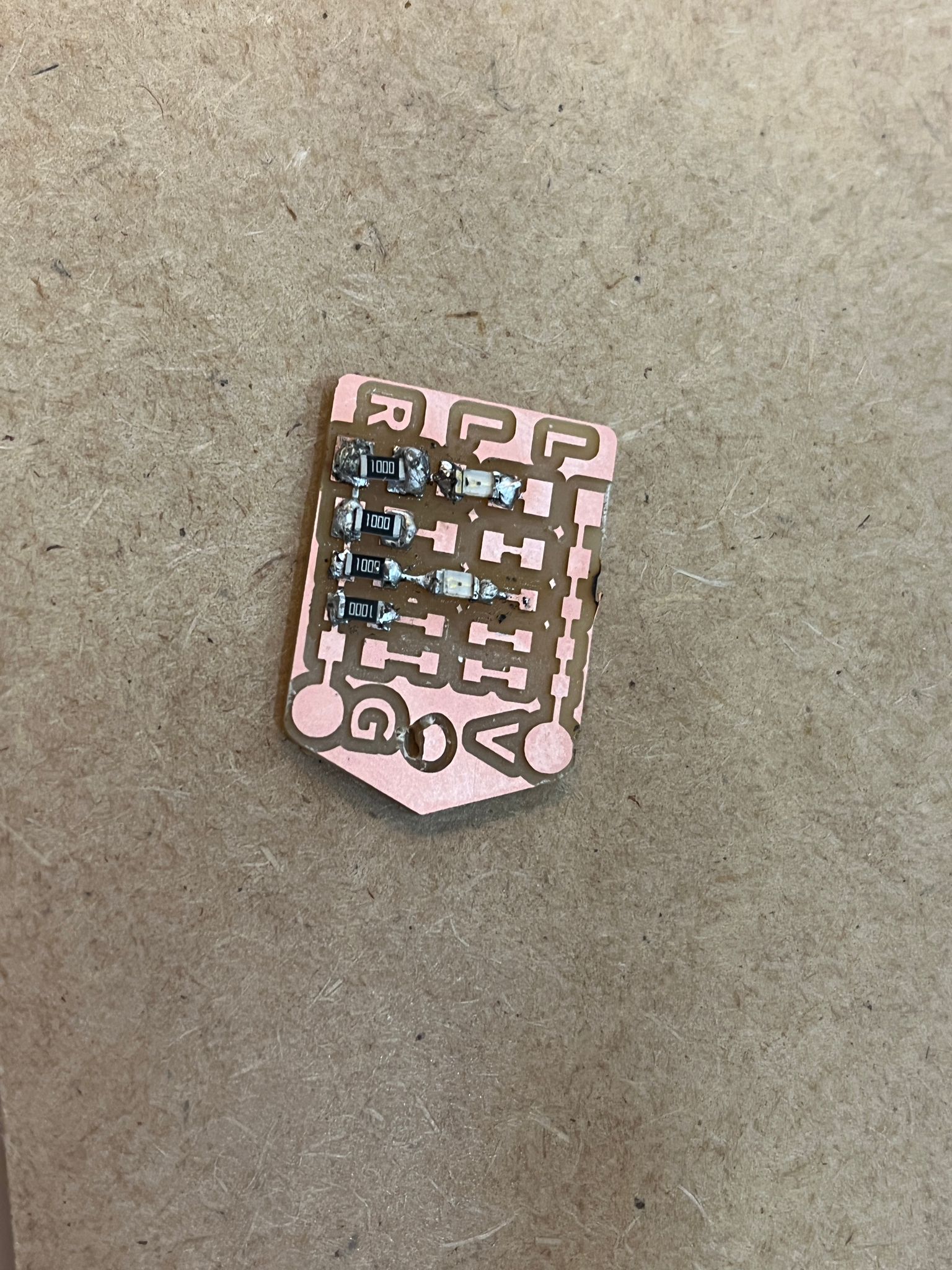

This week we focused on PCB ( printed circuit board) manufacturing, PCBs are good for preventing short circuits and are a good way for milling non toxic materials. The PCB is a milled sheet of copper that has pads and signal trace structures from a digital circuit board, also known as a a lay out file. In the Fab Lab Barcelona facilities, we have access to the The Roland monoFab SRM-20.

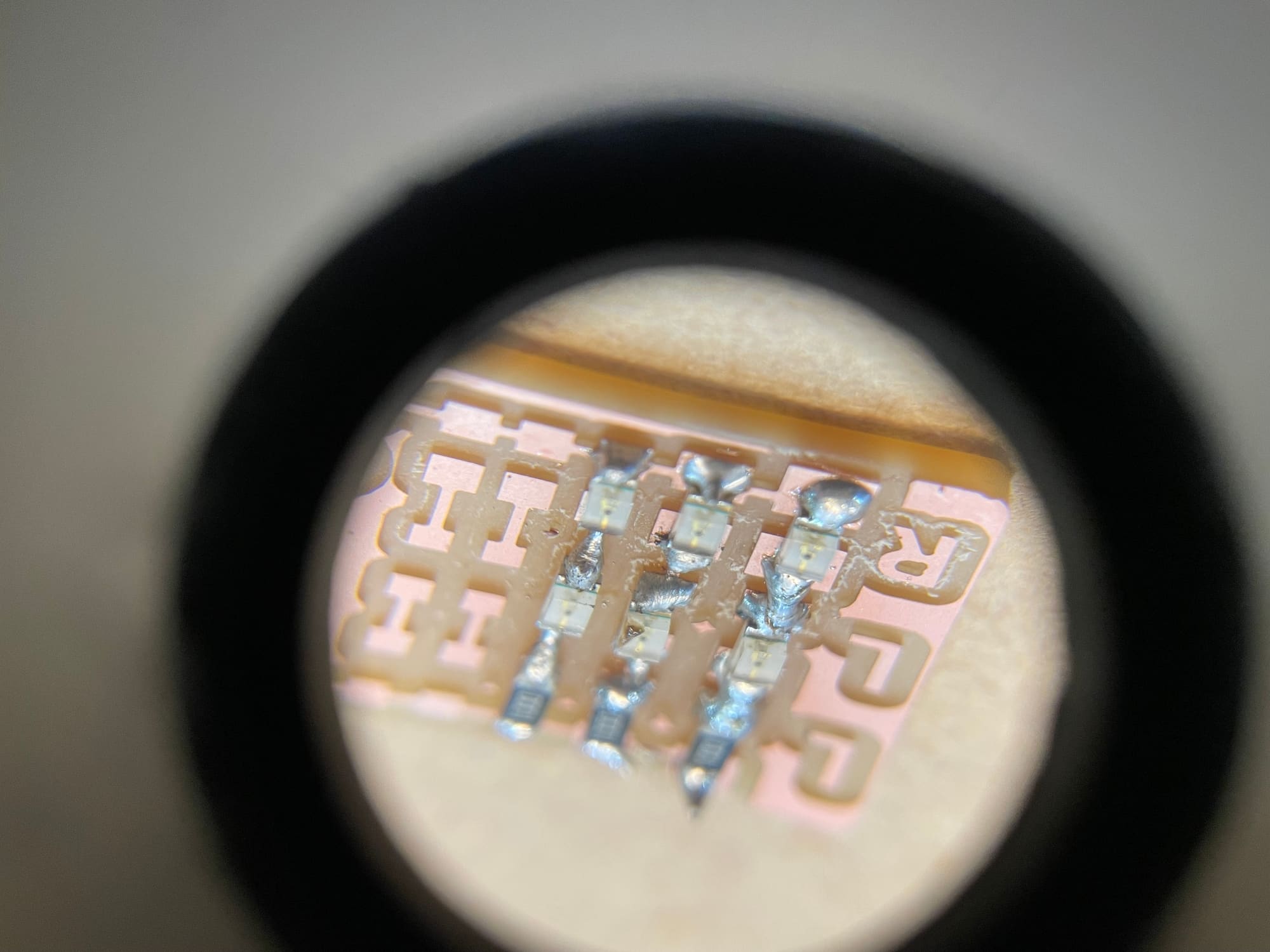

Most common materials used for milling are phenolic resin, epoxy resin, and polyester resin. We learnt how to solder a line for LED lights on a pre-cut PCB board. It was fascinating to read about the amount of effort that goes into creating a little chip that is found in practically every electrical gadget we own. Of course, in today's world, this isn't the case.

Soldering a PCB Board.

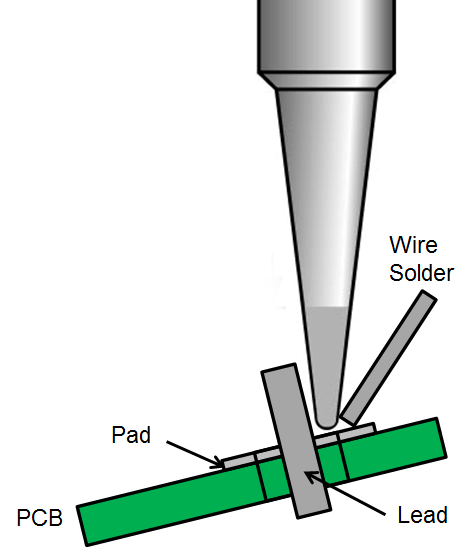

Soldering is a process in which two or more items are joined together by melting and putting a filler metal into the joint, the filler metal having a lower melting point than the adjoining metal.

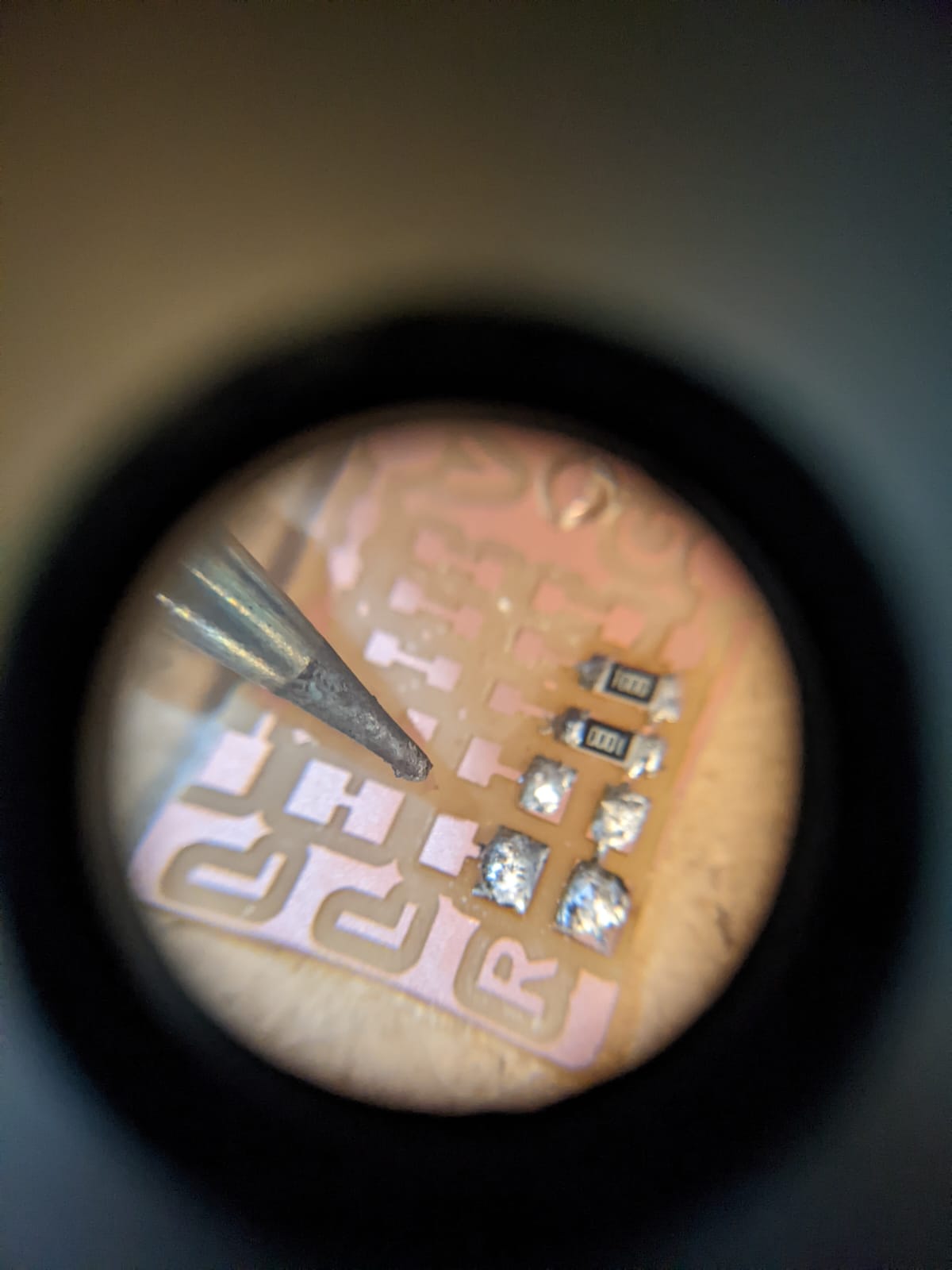

How to solder:

- Clean the soldering surface

- Turn on the soldering iron and set the melting point of the solder

- Hold the tip of the leand and contact point

- Touch the solder wire to the contact pint until it flows around the lead

- Make sure there is coverage of the contact area, forming a slight pyramid shape

also during the same week of our first micro challenGe. The task was a bit smaller this week, where we had to finish a LED badge by soldering the SMD components and light it with a power supply We had a soldering session, where we were shown the correct way to solder using the Roland SRM-20 mill.